SAFETY

An approach built from the ground up, based

on the care every BNSF team member

brings to our colleagues, our communities and

the freight that we move.

THIS IS BNSF

BNSF Safety Vision

Our employees inspire us to embrace a vision of operating free of accidents and injuries. We aspire to prevent safety incidents in the first place through training, technology and safety programs.

Prevention

35 million messages are generated daily by our network of 4,000+ trackside detectors to help us identify defects before they create an issue.

Mitigation

Though BNSF does not own the tank cars we use to ship ethanol and crude oil, we work with our customers to ensure we have the safest tank cars in which to move these commodities.

Response

BNSF trained 6,800+ first responders in 2018.

Recognizing Our Employees’ Commitment to Safety

Every year BNSF celebrates several employees who embody our commitment to safety by recognizing them as Safety Employees of the Year. Key considerations for the honor include demonstrating leadership in our safety programs, promoting safety through innovative ideas and proactively identifying risks and reinforcing safe behaviors with positive feedback. Safety Employees of the Year for 2018 include Humberto Briones Jr. (Intermodal), Dan Drobny (Engineering-Track & Structures), Phillip Jody (Engineering-Signal & Network Control Systems), Alejandra Sanchez (Engineering-Telecommunications), Tohmer Soltes (Mechanical) and Jessica Stone (Transportation).

"There are a lot of people at our facilities. I may not know you, but you should know I’m going to look out for you. I learned that as a Marine, and it applies at the railroad as well."

Intermodal Safety Employee of the Year

Seattle, Washington

"Our team just celebrated 17 years injury-free. We take care of ourselves and look out for each other to make sure no one gets hurt and everyone goes home the same way they came to work – and back to our family, kids and grandkids."

Engineering-Signal & NCS Safety Employee of the Year

Winslow, Arizona

Training Our Team

BNSF trains our employees on an array of technical rules and safety topics, including federal regulations, rail industry recommendations and BNSF-specific initiatives. A key venue is the BNSF Technical Training Center (TTC) in Overland Park, Kansas. There, employees take courses and utilize simulation and lab tools that represent equipment, including locomotives, cranes and crossing gates. In 2018, we trained more than 4,300 employees at TTC and close to 20,000 in the field, as well as more than 500 rail industry employees.

Approaching Others About Safety

Our Approaching Others About Safety initiative continued strong in 2018. The initiative is designed to address the risk associated with the exposures that result in 97 percent of the fatalities and serious injuries in the rail industry. In 2018, more than 20,000 employees received Approaching Others About Safety training.

Injury Prevention

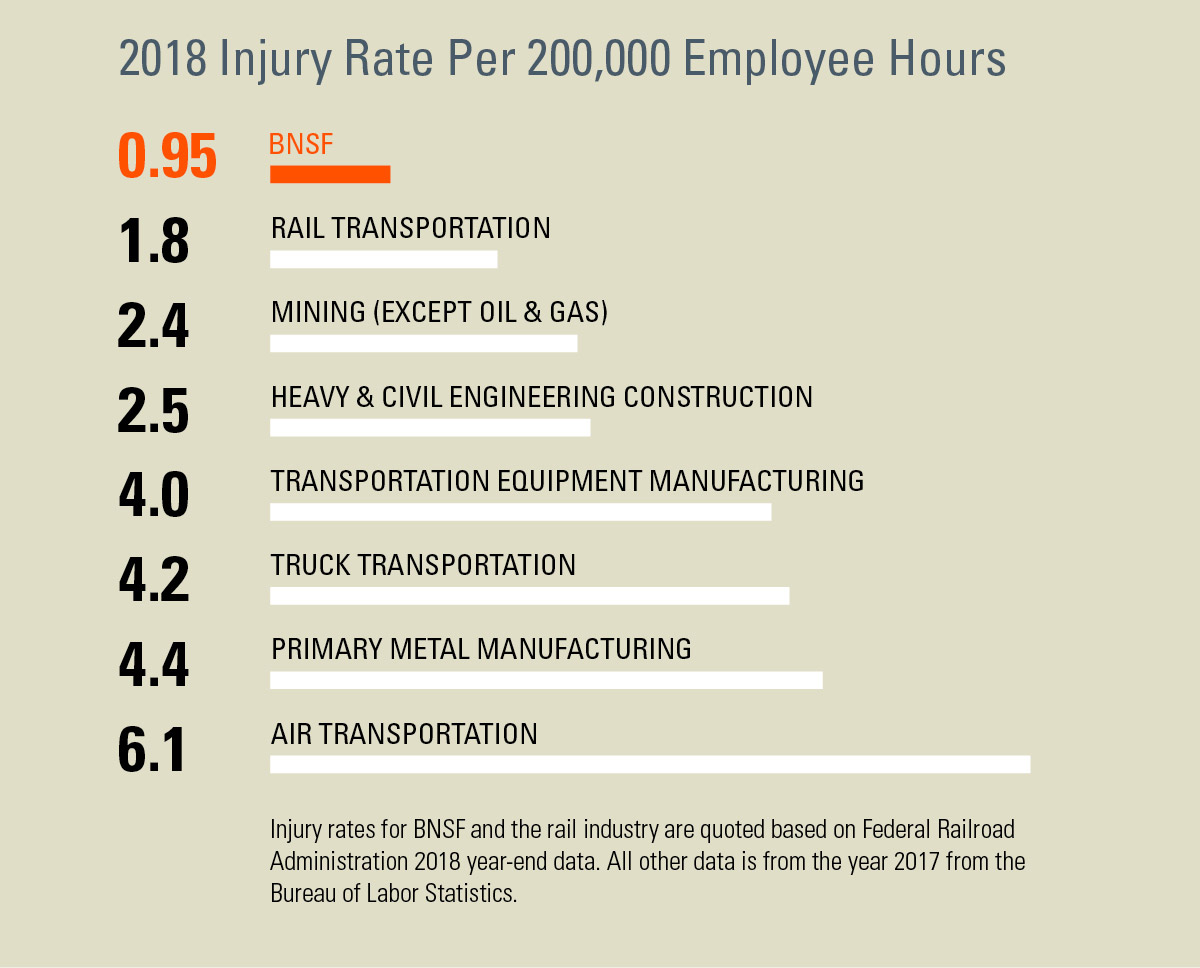

The U.S. rail industry has made significant gains in safety over the years, and BNSF is a leader in this area.

First Responder Training

BNSF continues to play a major role in training emergency hazmat responders in the communities in which we operate. In 2018, we helped train more than 6,800 first responders. This training is provided by BNSF and railroad industry partners through the Transportation Community Awareness and Emergency Response (TRANSCAER) program.

Hazmat Response Resources

BNSF maintains a network of more than 250 hazardous materials responders who are trained to handle situations from small non-accident releases to major releases. To support their efforts, we have strategically placed emergency response equipment at more than 70 locations across our network.

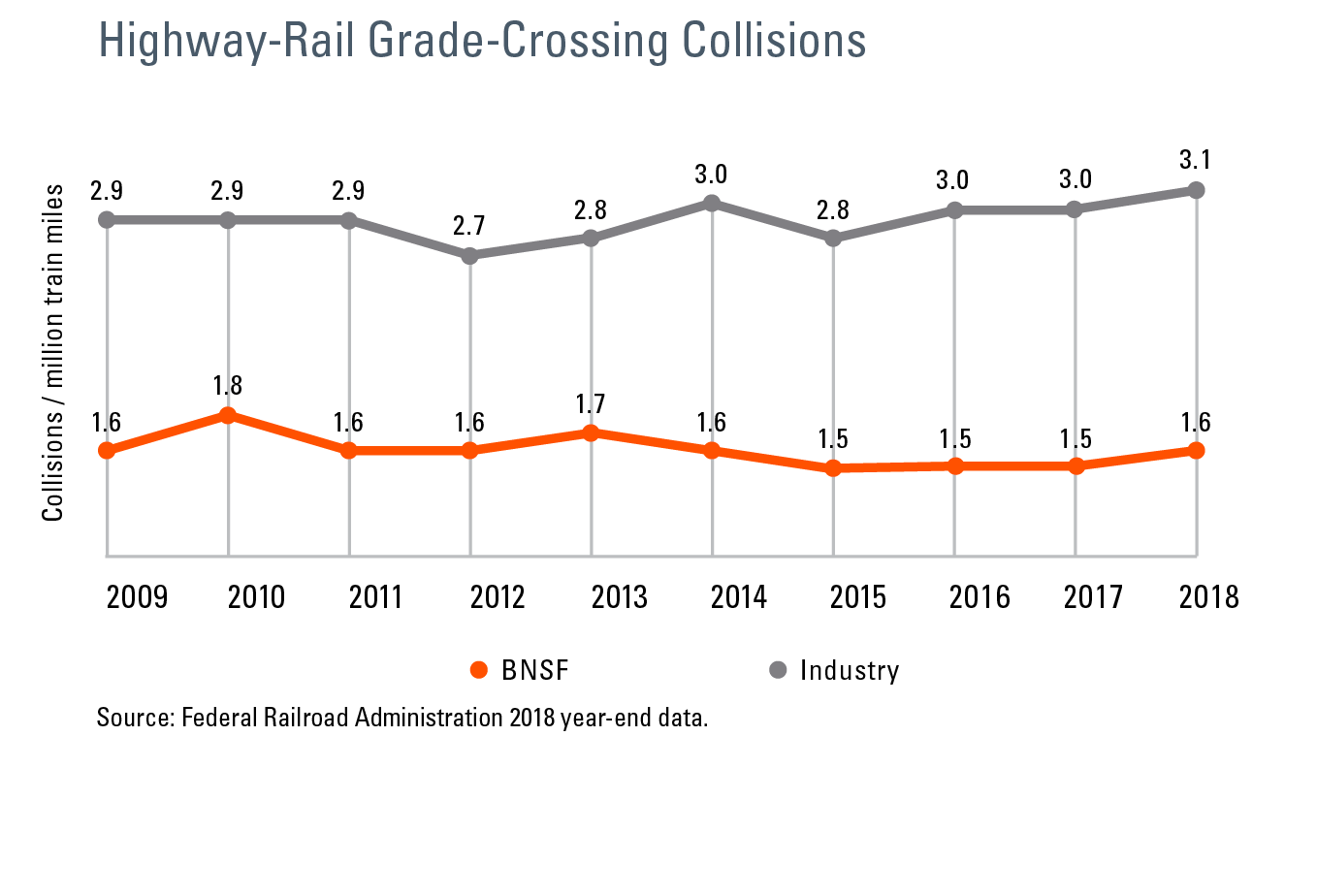

Grade-Crossing Safety

BNSF has achieved one of the industry’s lowest highway-railroad grade-crossing collision rates. In collaboration with communities and landowners, we have been able to close more than 6,400 grade crossings since 2000. We also regularly participate in programs such as International Level Crossing Awareness Day in communities across our network. For the past several years, BNSF has spent an average of approximately $140 million annually on programs related to grade-crossing safety, including approximately $80 million on grade-crossing maintenance.

Positive Train Control

At BNSF, we are leading the North American freight rail industry in the implementation of Positive Train Control (PTC). In fact, we completed installation of all federally mandated PTC infrastructure on our network in 2017, well in advance of the December 31, 2018, deadline. We are also installing PTC in locations beyond the mandate. Nevertheless, in 2018 we requested an extension, because to be considered fully implemented requires that all other railroads operating across any of our PTC-equipped lines must also be capable of operating with our PTC system.

Moving forward, our focus will continue to be on PTC interoperability. We have achieved interoperability, and PTC is active for several passenger railroads, including Amtrak, where they run on BNSF. This is an important achievement because one of the primary purposes of PTC is to provide protection where railroads run freight and passenger service. We have also accomplished interoperability with several shortline railroads.

We look forward to expanding interoperability and continue to work with the Federal Railroad Administration to ensure PTC enhances rail safety wherever it operates.

Extensive Inspections

BNSF regularly conducts rigorous track, weather event, bridge and rail inspections across our network that meet all federal requirements. Efforts include routine visual inspections by specially trained track and bridge inspectors. We supplement their inspections by leveraging sophisticated instrumented railcars and trucks, bridge inspection vehicles and unmanned aerial vehicles. These various tools are equipped with a variety of high-tech capabilities including track measurement systems that use ultrasound for internal rail inspections and ground-penetrating radar, high-definition cameras and accelerometers used to analyze the roadbed, track and bridges.