BNSF Safety Vision

At BNSF, our vision for safety is to operate free of accidents and injuries. Empowered by training, programs and technology and guided by our firm belief that every accident or injury is preventable, we all work every day to make sure our safety vision is reality.

Extensive Training

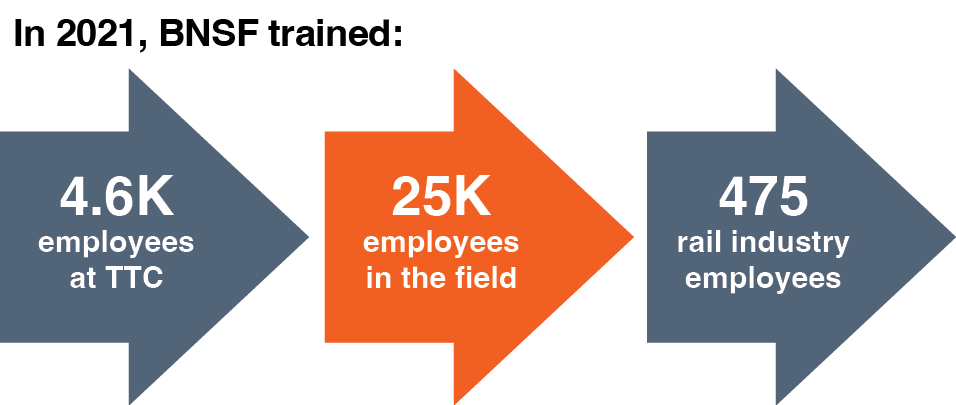

BNSF adopts a multi-faceted approach to employee safety training, including formal training programs built around technical rules, rail industry recommendations and federal regulations. We also deploy BNSF-specific initiatives developed and conducted by BNSF team members. Our ongoing efforts combine field, on-the-job, long-distance and technical training. At the BNSF Technical Training Center (TTC) in Overland Park, Kansas, BNSF team members (and other rail industry employees) take courses and simulate the safe operation of equipment such as locomotives, cranes and crossing gates.

Recognizing BNSF Safety Champions

We celebrate safety at BNSF with internal recognition including the Safety Employees of the Year and Safety Bells award programs.

2021 Safety Employees of the Year

Recognizing team members in multiple departments who embody the BNSF commitment to safety.

- Transportation – Adam Florine, locomotive engineer, Lee’s Summit, Missouri (reports to Chicago Division)

- Mechanical – Chris Craven, machinist, Havre, Montana

- Engineering/Signal – Darrell Lippe, signal inspector, Temple, Texas

- Engineering/Track & Structures – Jason Cox, gang foreman, Centralia, Washington

2021 Safety Bell Recipients

Recognizing BNSF teams that achieve the lowest reportable injury-frequency ratios.

- Best Overall Division (all crafts combined) – Kansas Division

- Best Transportation team – Red River Division

- Best Mechanical Shop team – Chicago Locomotive: Corwith and Cicero Locomotive and Service Track

- Best Field Mechanical team – Southwest Division

- Best Engineering team – Heartland Division

Hazmat Safety

Rail is one of the safest ways to transport hazardous materials – 99.999% of BNSF hazmat shipments reach their destination without a release caused by a train incident. Through resources and training, BNSF remains committed to transporting these materials as safely as possible.

We have a network of more than 150 hazardous materials responders and advisors in place who are trained to deal with all types of hazmat releases. BNSF has also strategically positioned emergency response equipment at more than 100 locations across our network.

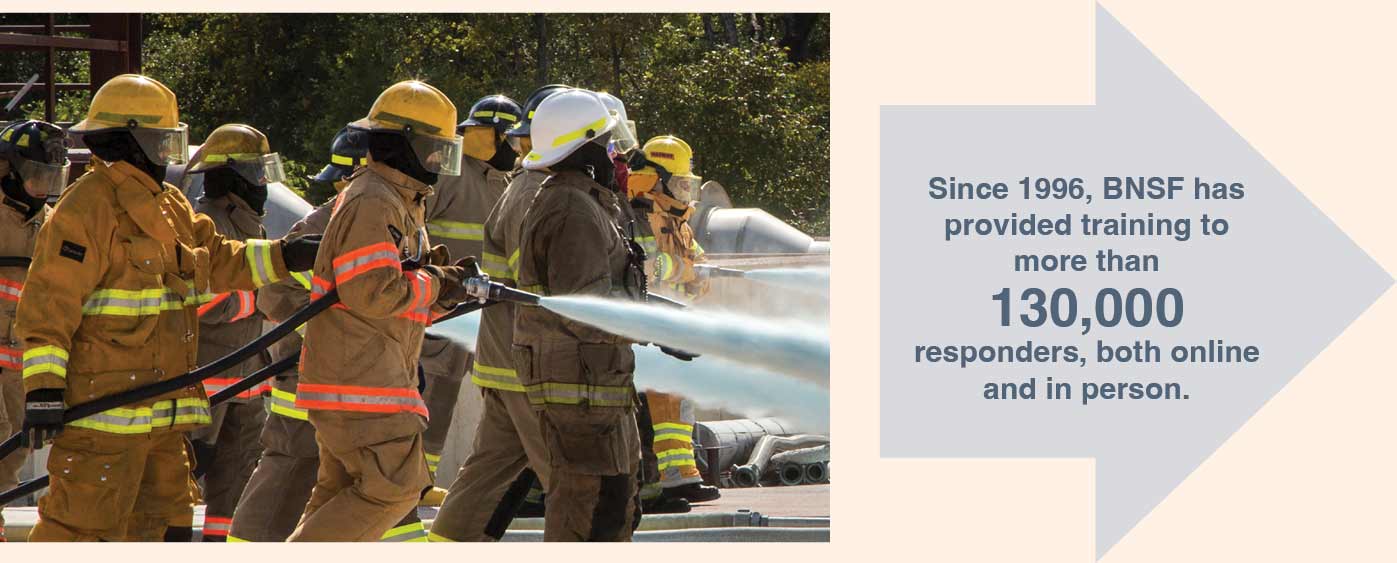

BNSF provides free training to first responders through the Transportation Community Awareness and Emergency Response (TRANSCAER) program. Through online and in-person sessions in communities across our network, we train 3,000 to 10,000 first responders a year in Railroad Emergency Response and Hazardous Material Awareness.

Grade-Crossing Safety

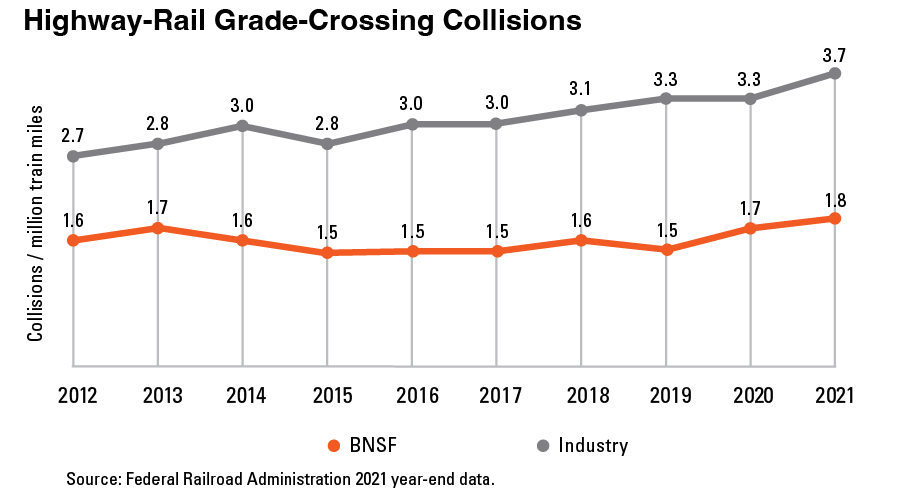

Through a variety of measures, BNSF maintains one of the lowest highway-railroad grade-crossing collision rates in the industry. Safety-enhancing efforts include community education and awareness campaigns, train crew education and testing, the deployment of new safety technology and crossing closures. Since 2000, BNSF has closed more than 6,200 grade crossings.

Positive Train Control

BNSF is a rail-industry leader in the implementation of the federally mandated safety system Positive Train Control (PTC). PTC uses global-positioning data to monitor train movement, providing warnings to crews, enforcing speed limits and stopping trains when certain conditions occur, such as a switch left in the wrong position. BNSF has installed PTC infrastructure on all of the 91 required subdivisions of our network and an additional 11 non-mandated subdivisions, covering more than 15,450 route miles and 93% of our freight volume. We continue to go beyond the federal mandate, installing PTC on additional subdivisions, and we are fully interoperable with other railroads that run on the BNSF network and are required to use PTC.

Intensive Inspections

BNSF regularly inspects all the components of our network, including locomotives, track, rail and bridges, and we also conduct inspections after weather events. These comprehensive inspections meet all federal requirements, and we are committed to timely maintenance, repair and replacement whenever issues or potential issues are detected. Trained BNSF inspectors utilize advanced equipment such as instrument-equipped rail cars, bridge inspection vehicles and unmanned aerial vehicles (UAVs) and deploy technology such as Machine Vision Systems (MVS), autonomous track measurement systems, ultrasound, ground-penetrating radar and high-definition cameras and accelerometers.

Fighting the Dixie Fire

In 2021, BNSF helped fight the devastating Dixie Fire in California. To coordinate efforts with other groups and agencies working the wildfire, both on the ground with fire engines, water tenders and bulldozers and from the air with helicopters, BNSF linked with the command center established with the California Department of Forestry and Fire. BNSF’s contributions included deploying fire trains with modified tank cars that have pump systems that enable us to fight fires and prevent their spread directly from the tracks. We also staged tank cars at strategic points to act as large fire hydrants and placed generators near telecommunications systems to prepare for power outages. During the wildfire, we re-routed or detoured trains to keep our customers’ shipments moving. BNSF prepares a Fire Action plan every year to ensure a coordinated response and efficient deployment of assets when fires occur.