We take our responsibility to care for the planet very seriously. Transport by rail by its very nature is the most sustainable way to move goods long distances over land. Think about it, locomotives are the power – the freight cars that they pull are along for the ride. This kind of efficiency reduces transportation emissions and carbon footprint. Plus, the more freight our trains take off congested highways, the lower the impact to the environment.

But that’s not enough. We have committed to achieving a 30% reduction in greenhouse-gas emissions (GHG) by 2030 (from a baseline year of 2018). We plan to do that in two primary ways: 1) by continuing to improve the fuel-efficiency of our locomotives, and 2) through the increased utilization of renewable fuels. Long-term solutions, such as battery-electric and hydrogen locomotives, are also being evaluated and field-tested.

Committed to 30% reduction in greenhouse-gas emmisions by 2030

When you see our orange locomotives’ and freight cars’ steel wheels moving on steel rails, think green. That’s because steel on steel creates less friction and expends less energy – more fuel efficiency – than a rubber tire on asphalt or pavement. Combine this benefit with the lower aerodynamic drag of a single train pulling hundreds of cars of freight and you can see the advantages over long-haul trucking.

In fact, freight trains are three to four times more fuel efficient and reduce greenhouse gas emissions by up to 75% compared to their highway counterparts. According to the Association of American Railroads, if 25% of truck traffic moving at least 750 miles shifted to rail, annual greenhouse gas emissions would fall by 13.1 million tons.

Another environmental benefit of freight rail: One single freight train can carry the equivalent of several hundred trucks, removing them from congested highways and roads. That means less time stuck in traffic, fewer engines idling and less air pollution.

Freight trains are 3-4X more fuel efficient than highway counterparts and lower greenhouse gas emissions by up to 75%

We’re not the only ones who think about being environmentally responsible. Sustainability has become a bigger contributing factor to customers’ supply chain decisions, with many setting net zero carbon targets that include supply chain emissions like rail transportation.

Our intermodal customers recognize that shipping with BNSF comes with many environmental benefits when compared to solely using trucks. In 2022, BNSF customers reduced their carbon emissions by more than 23.9 million metric tons. That savings is the equivalent of removing approximately 5.2 million vehicles’ resultant emissions.

Still, we know that we can ALL do a better job taking care of our planet and improving community sustainability. That starts with setting achievable goals and taking actions. At BNSF, our goal is to reduce GHG emissions by 30% by 2030. We know that locomotive fuel consumption made up about 80% of our GHG emissions in 2018, so that’s our baseline, and we are planning further reductions beyond 2030.

In 2022, our customers managed to reduce their total carbon emissions by 23.9M metric tons

With a 2030 goal established, the actions we’re taking to achieve that are: adopting more fuel-efficiency measures, using renewable fuels, advancing energy technology and more, like electrifying equipment at our intermodal hubs. Here are some of the specifics:

BNSF is proud to have the largest number of the newest and cleanest-burning locomotives in North America, including more than 300 Tier 4 locomotives purchased since 2015 when the new Environmental Protection Agency standards took effect.

We have equipped more than 4,000 locomotives with Energy Management Systems, such as Trip Optimizer, which allows the throttle and dynamic brakes to be controlled automatically, like cruise control. EMS factors the train makeup (length, weight, and horsepower), track geometry, grade, curvature and speed restrictions to determine the most fuel-efficient way to operate the train across a territory while maintaining appropriate train handling.

Automatic Engine Stop/Start (AESS) is another fuel-saving system. AESS automatically shuts down a locomotive that is idling to minimize wasted fuel and eliminate unnecessary emissions. AESS then automatically restarts the locomotive if it’s needed for power or necessary for the health of the engine. Currently, more than 99% of our active locomotive fleet is AESS-equipped.

And it’s not just technologies that help reduce our impact, but how we operate. Reducing the horsepower per trailing ton (HPT) – the effort to move the weight of a train – is one of the most effective methods to improve fuel efficiency. Practices we have implemented to minimize HPT include reducing excess horsepower; implementing speed-based throttle limiting, which reduces fuel consumption at higher speeds; and isolating, or potentially shutting down, engines when a train has more locomotives than it needs for a given segment of its route.

While finding the optimal blend of the two fuel sources is a challenge, we are optimistic that the future benefits of blending these lower carbon fuels could provide an estimated benefit of up to 20% carbon reduction by 2030, if feasible and available. Biodiesel is a more affordable alternative fuel option but comes with the possibility of issues in large locomotive engines. Renewable diesel, on the other hand, is the more expensive alternative fuel source with less availability across our network but is chemically similar to current petroleum fuel sources.

In 2022, we began testing a B20/R80 blend of fuel which is a mixture of 20% biodiesel and 80% renewable diesel. The pilot involves our partnership with locomotive manufacturers using a Barstow, California-based fleet of engines over a three-year period to test the fuel blend with the machine components. By working with our locomotive manufacturing partners, we hope to continue to make positive strides in increasing the amount of biodiesel and renewable diesel fuels we can use to operate our locomotives, which would translate into significant carbon intensity and emission reductions for our fleet.

Here’s how it worked: The battery-powered locomotive was situated between two Tier 4 diesel locomotives, creating a battery-electric hybrid consist that powered the train. The battery-electric locomotive was charged in Stockton and then once on the road, stored additional energy through dynamic braking (i.e., kinetic energy captured while braking).

BNSF is moving forward with next-gen locomotives including partnering with Progress Rail to demonstrate an 8-megawatt hour battery-electric locomotive and a hydrogen fuel cell locomotive starting in early 2025.

We plan to perform commercial and operational testing of these locomotives in yard, local and regional service. Our rule-of-thumb is to get 30-to-50 locomotive years of experience with each model before incorporating within commercial and operational use. This would include switch engines, for moving cars to and from local customer facilities to our yard for an in- or out-bound train, as well as rebuilding trains within our yard. In addition, we are testing a variety of next-generation (battery-electric and hybrid-powered), cargo-handling equipment at three of our California intermodal facilities. Electric cargo-handling equipment operates much quieter, more efficiently and cleaner than our traditional diesel machines, contributing to a safer and more comfortable work environment while reducing impacts on surrounding communities.

We currently have 35 battery-electric yard trucks, or hostlers, operating in our California intermodal facilities, with plans to add another 50 in the next two years, and we will soon deploy 10 units at our South Seattle intermodal facility with plans to continue converting diesel models to electric. Alongside our hostlers, we are testing charging infrastructure at our facilities with smart charging capabilities to allow for lower power usage based on how often the charging stations are used. The potential result is a substantially lower emissions footprint with savings in fuel cost.

Our Stockton yard is the first fully electric hostler facility in the United States, with 21 hostlers and a hybrid-electric rubber-tired gantry crane, which reduces emissions by 90%. Additionally, our Stockton facility has a 0.75 mega-watt solar array providing renewable energy back to the facility’s electrical grid.

We’re also looking at a variety of technologies alongside battery power. In 2021, we announced plans to work with Progress Rail and Chevron to pilot a demonstration of a locomotive powered by hydrogen. This technology could one day be a lower-carbon solution for line-haul service, as it has the potential to reduce carbon emissions over long distances.

Keeping Our Orange House Green

Other ways we keep it green in our workplace:

- Ensuring our locomotives and railcars are kept in top condition for best performance

- Lubricating rails to reduce friction between the wheels and the rails

- Powering some of our facilities with solar energy, including back-up power for signals

- Optimizing automated in-gate systems at our intermodal facilities with advanced technology

- Using wide-span electric cranes that produce zero emissions on-site and significantly reduce the number of trucks needed to move containers in our intermodal facilities

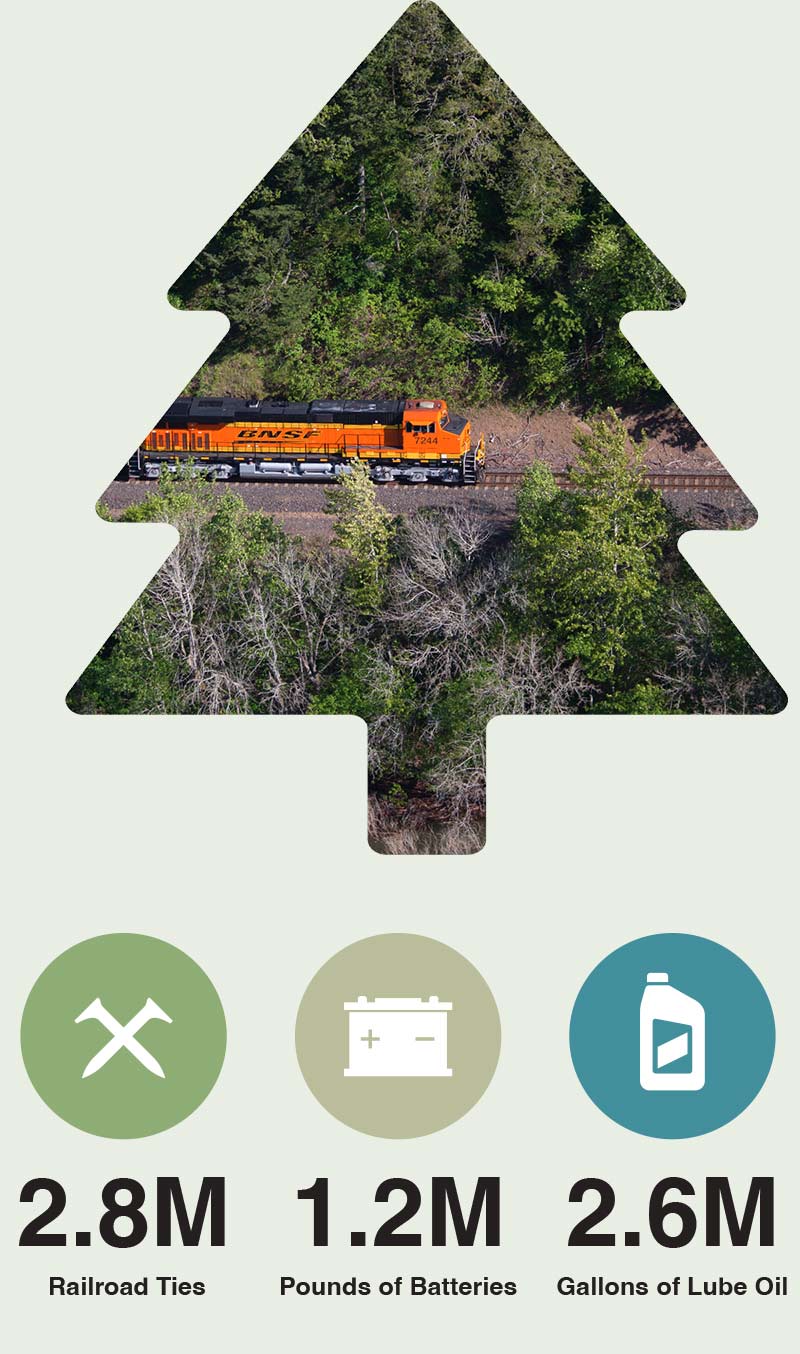

- Recycling, renewing and reusing (in 2022, our railroad recycled approximately 2.8 million railroad ties, 1.2 million pounds of batteries and 2.6 million gallons of lube oil)

- Rehabilitating old railroad sites to reduce environmental impact

- Auditing facilities and participating in risk-mitigation efforts, as well as following environmental stewardship practices

- Improving freight fluidity by looking holistically at our network to understand where investments are needed most in track and infrastructure to keep trains moving rather than holding

- Advancing the site restoration process by using less-invasive drones to analyze plant species and site conditions

- Communicating and collaborating with our suppliers about sustainability and their role, especially as Green Partner Suppliers

Linking Supply Chain Sustainability

Another way we help our customers reduce their environmental impact is through our Logistics Centers and Certified Sites, which create a more sustainable, streamlined supply chain by being positioned near growing markets.

- Logistics Centers are multi-customer, multi-commodity business parks that offer direct rail in growing markets. They are highly efficient, which reduces emissions and environmental impact and generates sustainable value for everyone.

- BNSF has a team of internal subject matter experts who thoroughly assess risks and opportunities associated with these locations, including potential environmental, social and economic impacts, to help ensure they are more sustainable.

- BNSF Certified Sites are areas of land adjacent to our network ready-made for customer development that reduce entry barriers for customers to gain access to rail-served sites. BNSF identifies real estate that could be readily connected to our network and studies environmental and social factors—such as wetland inventories and community outreach—to minimize potential impacts that could delay or stop a development project.

- We also work with our customers to grow sustainable business markets. These markets include emerging energy markets (i.e., solar & wind power, battery storage and transmission infrastructure), and closed loop supply chains where waste materials are “upcycled” into products (i.e., renewable diesel, low carbon cement and advanced recycling of plastics).

- We are teaming up with transportation partners, including intermodal trucking and ocean shipping companies, to build green transportation corridors and hubs. These green corridors are targeted toward consumer products customers with net zero targets.

Celebrating Sustainability

Starting in 2022, BNSF honored customers with our inaugural BNSF Sustainability Awards for success in making their operations more sustainable. The BNSF Sustainability Awards will be presented annually to companies that are challenging the status quo when it comes to implementing sustainable practices and supply chains in their respective industries. Click here for a list of the six who were honored in 2022.

Greening Our Communities

Our BNSF Railway Foundation is one of the ways we support the communities we serve. Among the many nonprofits the foundation funds are civic services, including those concerned with the environment and conservation.

The men and women of BNSF take great pride in our work as well as the role our railroad plays in reducing the environmental impact to the planet. We do our jobs for a lot of reasons, including helping to sustain the communities in which we live and work. We are champions of strong, livable communities because where we operate is also our home. And like you, we think a lot about how to keep it green and clean.

BNSF Sustainability Overview

BNSF Sustainability Overview